Quadron Pillarhouse: versatility and precision

Fluxing system

The Quadron system ensures consistency and repeatability in flux application through a crucible or sprung test probes that deliver flux directly to the terminals, avoiding contamination of the bobbin. Immersion height and duration are precisely controlled by stepper motors, minimizing excess flux and insulating material residue. The system is available with either a fixed flux bath or a tin recycling reservoir that reduces flux evaporation.

Soldering

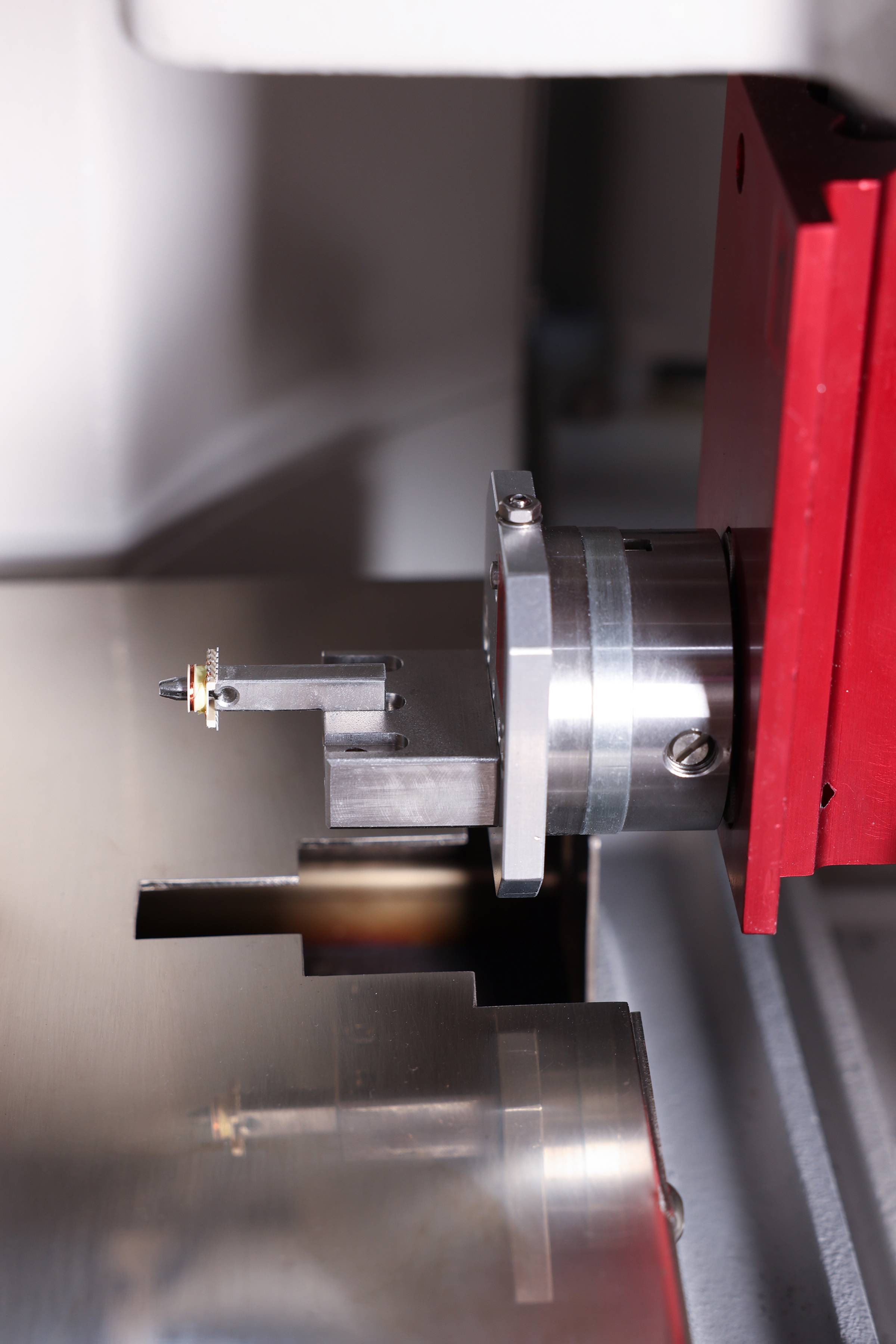

Quadron features a reliable solder pump system with customizable nozzles. Doss is removed from the nozzle before the next soldering operation by increasing pump speed, expelling tin from the nozzle. This occurs during the index operation and does not impact overall cycle time.

Components are immersed in tin using a precision stepper-motor-driven slide, ensuring highly accurate, precise, and repeatable results.

For optimal soldering quality, Pillarhouse can equip the machine with a nitrogen diffuser at the soldering station, significantly improving soldering outcomes by reducing oxide formation and preventing solder bridges.

A key advantage of the Quadron system is its ability to tilt components during tin extraction, a critical feature for avoiding bridges on fine-pitch connectors.

Programming

Quadron is easy to program via a 7" LCD display and keypad, offering complete control over tin bath temperature, flux and tin immersion height and timing (in increments of 0.1 mm and 0.1 seconds). The system is suitable for soldering a wide range of components, including coils, transformers and small PCBs.

Additional features include component testing, unloading functions and a weekly auto-start timer for pre-shift preheating.