WT products

Coil winding machines

Winding Technology offers a comprehensive range of precision machines and accessories for coil winding and transformer production.

The product line includes both benchtop and floor-standing machines, designed to meet diverse production requirements. The range of centre distances, from 150mm on the WT150 model to 1500mm on the WT1500, allows flexibility to accommodate various coil sizes.

Rotor banding machines

WT has developed a range of advanced machines for high-speed banding of permanent magnet rotors using pre-impregnated carbon fibre, Kevlar or glass tape. These machines precisely control tape tension and the unwinding system to ensure flawless banding. WT has introduced groundbreaking innovations for this application.

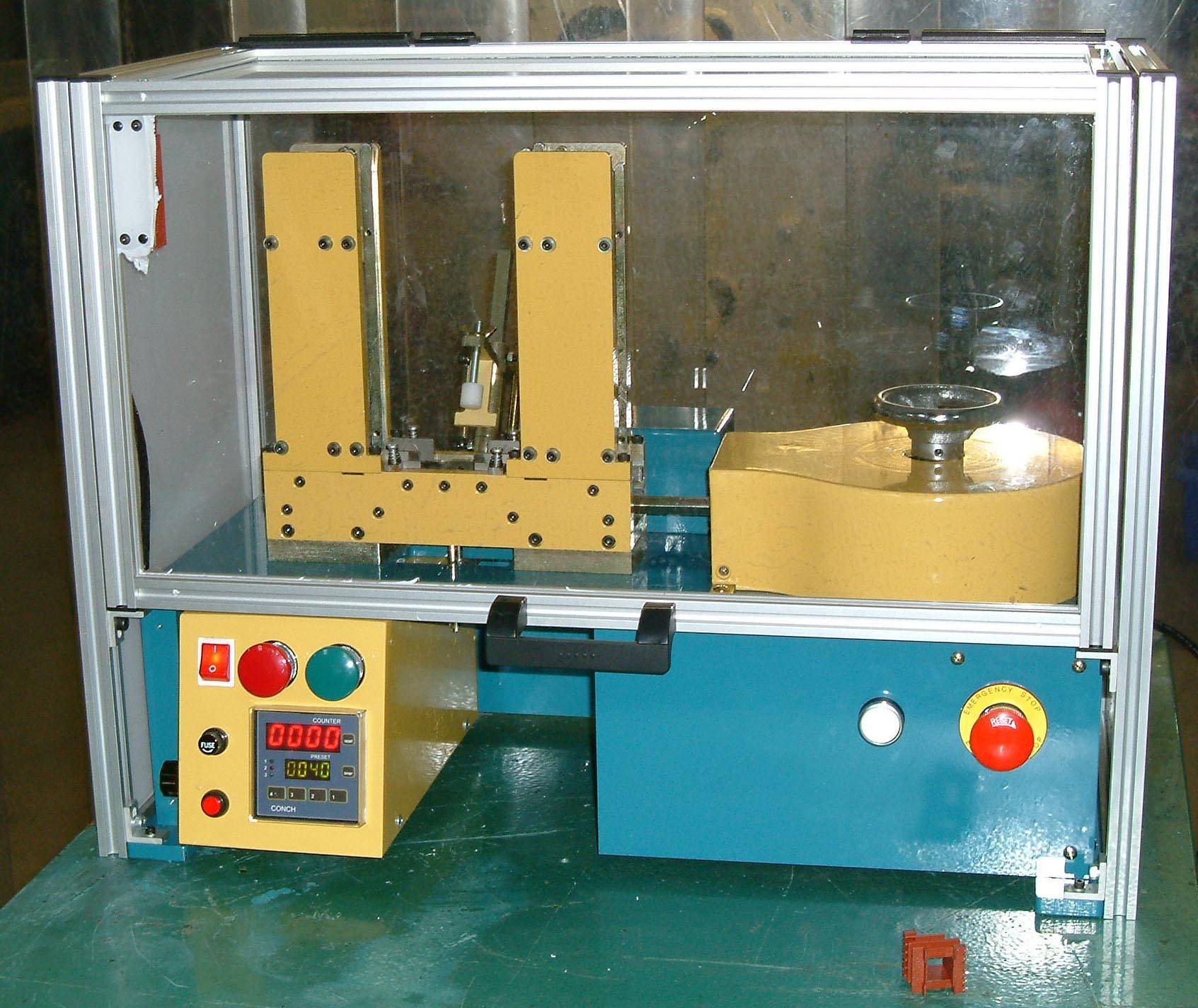

Lamination Stacking Machines

Winding Technology lamination stacking machines are available for E&I transformer laminations, with sizes ranging from EI-28 to EI-209.

Special machines are also available for:

- Non-standard laminations (UI & EE)

- Nickel type laminations

- Small laminations – machines designed to insert only the E lamination (down to size E19)

The machines, also available in a motorized and fully safe version, are built for a specific lamination size but adjustable for different steel thicknesses, ensuring up to 60% time reduction compared to manual interleaving.

Special machines

Winding Technology is deeply committed to research and development, offering a full design and manufacturing service to deliver bespoke solutions tailored to customers' specific needs.

The PCWM software can be customised to include additional screens, simplifying the programming of complex operations and reducing operator error.

Some completed projects include:

- Fibre optic coils wound using a dual wire-guiding system, allowing simultaneous winding of two coils.

- Resistance coils wound with vertical corrugated tape.

- Small-diameter sensor coils with lengths up to 2 metres.

PCWM control: one of the most powerful and user-friendly systems on the market

All WT winding machines are equipped with the PCWM control system, celebrated for its exceptional performance and user-friendly design. Developed over more than 20 years, it features an intuitive touchscreen interface that is easy to navigate and learn.

Built on the Windows operating system, it seamlessly integrates with corporate networks and supports remote online diagnostics.

Rebuilt machines

Recognising the importance of maximising the lifespan of your machinery, WT offers a refurbishing service for existing or redundant winding machines. This includes the option to upgrade with WT’s latest control systems, providing a cost-effective alternative to purchasing new equipment.

After reconditioning, the machines are restored to like-new condition and fully compliant with current manufacturing standards.

All reconditioned machines come with a 12-month warranty on mechanical components and a 3-year warranty on electrical components.